Difference between revisions of "Technics RS-1500 US"

| (192 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

__NOTOC__ | __NOTOC__ | ||

| − | == | + | == Data == |

| − | {{ | + | {{navigation}} |

| − | ''' | + | '''General''' |

| − | * | + | * Manufacturer: [[Technics]] |

| − | * | + | * Model: RS-1500US |

| − | * | + | * Years of manufacture: 1976 to 1986 |

| − | * | + | * Made in: Osaka, Japan |

| − | * | + | * Color: black |

| − | * | + | * Remote control: optional with RP-9690 (wired remote control) or RP-070 (infrared remote control) |

| − | * | + | * Power consumption: 120 W |

| − | * | + | * Dimensions: Width:456 mm, Height: 446 mm, Depth: 258 mm. |

| − | * | + | * Weight: approx. 25 kg |

| − | * | + | * Original price approx.: 2,630 DM to 3,000 DM |

| + | Option 2-track headstock RP-2224: 399 DM | ||

| + | Option 4-track headstock RP-2422: 399 DM | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''Connections''' | ||

| + | * Number of outputs: 2 | ||

| + | ** Headphones: 80 mV/8Ohm | ||

| + | Line Out: 0.5 V (OVU)/at 22 kOhm or more | ||

| + | ** DIN: No | ||

| + | * Number of inputs: 3 | ||

| + | ** Microphone: 0.25 mV (-72 dB)/4.7 kOhm | ||

| + | ** Line In: 60 mV (-24 dB)/150 kOhm | ||

| + | ** Trough Out: 60 mV (-24 dB)/150 kOhm | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ''' | + | '''Technical Data''' |

| + | max.coil diameter: 26,5 cm | ||

| + | Drive: Direct-drive, brushless DC motor with phase-locked quartz control for the tone shaft (from turntable e.g. 1210), two direct-drive, brushless DC motors with tape tension control for the winding plates | ||

| + | * Heads: 4 tone heads (head carrier: RP-2224) | ||

| + | * Tracks: 2-track, 2-channel stereo record/playback and 4-track, 2-channel stereo playback | ||

| + | * Tape speeds: 9.5 cm/s, 19 cm/s and 38 cm/s | ||

| + | * Slip: | ||

| + | ** at 9.5 cm/s: 0.018% (WRMS) +/-0.035% DIN) | ||

| + | ** at 19 cm/s: 0.03% (WRMS) +/-0.06% DIN) | ||

| + | ** at 38 cm/s: 0.06% (WRMS) +/-0.12% DIN) | ||

| + | * Pitch fluctuations: | ||

| + | * Overall frequency response: | ||

| + | ** at 9.5 cm/s: 20 - 15,000 Hz, +/-3 dB | ||

| + | ** at 19 cm/s: 20 - 25,000 Hz, +/-3 dB | ||

| + | ** at 38 cm/s: 30 - 30,000 Hz, +/-3 dB | ||

| + | * Signal-to-noise ratio: | ||

| + | * extraneous signal-to-noise ratio (pickup level = 3% total harmonic distortion): | ||

| + | ** at 9.5 cm/s: 66 dB | ||

| + | ** at 19 cm/s: 68 dB | ||

| + | at 38 cm/s: 68 dB | ||

| + | * Total harmonic distortion (0 VU): 0.8% | ||

| + | * crosstalk fluctuation (38 cm/s): 0.05% | ||

| + | * Crosstalk attenuation at 1 kHZ in stereo mode: 50 dB | ||

| + | * Cancellation attenuation: at 19 cm/s: 65 dB | ||

| + | * Premagnetization and extinction frequency: 120 kHz | ||

| − | + | '''Special Features''' | |

| − | + | * Speed fine adjustment (record/playback): +/-6%. | |

| − | + | * Four-digit tape counter, at 38 cm/s display of real time, at other tape speeds must be converted. | |

| − | * | + | * "Isolated Loop" tape guide |

| − | * | ||

| − | |||

| − | |||

| − | == Berichte == | + | '''Accessories (for pictures see [[Technics_RS-1506_US|RS-1506US]] and [[Technics_RS-1700|RS-1700]])''' |

| + | * RP-9100 flight case (1) | ||

| + | * RP-9110 Hard plastic dust cover to put on when coils are mounted (2) | ||

| + | * RP-9120 Wooden side panels (Rio rosewood, veneered, thickness of side panels: 3 cm) | ||

| + | * RP-9130 Brackets for shelf mounting (3) | ||

| + | * RP-9690 Cable remote control for RS-1500US and RS-1506US (4) | ||

| + | * RP-9170 Cable remote control for RS-1700 | ||

| + | * RP-070 Infrared remote control with receiver and transmitter (see [[Technics_RS-1700|RS-1700]]) | ||

| + | * RP-10A 26.5 cm aluminium empty reel (5) | ||

| + | * RP-2422 quarter-track headstock (7) | ||

| + | * RP-086 Battery adapter for 24 V DC operation | ||

| + | |||

| + | |||

| + | == Remarks == | ||

| + | * The machine is not EE tape compatible! | ||

| + | |||

| + | * Technically, the machine is identical to the [[Technics_RS-1506_US|RS-1506US]]. Audio head carrier on the RS-1500US is the RP-2224 (2-track record playback/4-track playback). On the RS-1506US, the audio head mount is the RP-2422 (4-track record/playback/2-track playback). Both headstocks can be interchanged at will between the two machines by loosening three screws. The RP-2224 and RP2422 headstocks also work on a [[Technics_RS-1700|RS-1700]], but here the autoreverse function is switched off. | ||

| + | |||

| + | Typical signs of age: | ||

| + | * Worn brake pads. The felt pads on the rewind motor brakes are usually worn and the tape throws loops when you switch from rewind mode to play mode. The looping causes the key control to shut down and cannot be used again until the tape is retightened. You can remedy this by replacing the old felt brake pads with suede. How to do this is described in detail at [[http://www.hifi-wiki.de/index.php/Technics_RS-1500_US#Berichte Tips for repairing Technics RS tape machines]]. | ||

| + | * Belt counter drive squeal. The drive pulley of the tape counter belt causes loud squeaking noises when rewinding. These squeaking noises disappear if you oil the axle of this drive pulley. | ||

| + | Worn out springs. If the machine has been standing around for years with the belt tensioned, the springs of the deflection pulleys are worn out. The machine will then no longer switch off when the belt has been unwound, as the deflection pulleys are no longer pulled completely upwards. The only remedy is to replace the springs. | ||

| + | In the black plastic caps of the toggle switches for monitor, tape select and rec mode there are small metal springs to push on and fix the caps. Over the years, the plastic becomes brittle and bursts, causing the springs to push the plastic apart and the caps to fall off. Burst plastic caps can be repaired by gluing them together with 2-component glue and then putting tight black heat shrink tubing over them and heating it with hot air. Without the shrink hose, the glued plastic caps will not hold in the long run, no matter which glue you use. As a replacement for the plastic caps, you can also use aluminum caps from old Pioneer units (SA-XXXX or SX-XXXX) that fit on the switch tabs. See Image: [http://www.hifi-wiki.de/index.php/Technics_SA-300#Bilder SA-300K]. | ||

| + | * Spare parts and accessories are no longer available from Panasonic or Technics. | ||

| + | * The AC power supply of the European version is switchable from 220V/240V to 110V/125V 50/60Hz. The American version is only designed for 110V/125V, but can also be operated on 220V/240V mains via an external transformer (so-called stepdown converter). The only important thing about such a converter is that it can handle the power consumption of the machine. | ||

| + | * Sending such a machine is a very delicate matter due to its heavy weight, as postal or parcel services are not exactly squeamish about such packages. I therefore recommend a personal delivery, even if you have to drive a few kilometers. Well packed, the Technics will even survive a trip across the pond. However, it is necessary to cover the front, back and sides with sufficiently thick polystyrene sheets. If the machine is only wrapped in crumpled up newspapers and styrofoam chips, the feet of the back or bottom panel or the switches, knobs or even the headstock on the front will inevitably punch into the machine when the package is thrown somewhere. | ||

| + | |||

| + | |||

| + | * Matching equipment from Technics: | ||

| + | ** Amplifier: SU-7300K, SU-7700K | ||

| + | ** Tuner: ST-7300K | ||

| + | ** Receivers: [[Technics_SA-300|SA-300K]], [[Technics_SA-400|SA-400]], [[Technics_SA-500|SA-500]], [[Technics_SA-600|SA-600]] | ||

| + | |||

| + | |||

| + | * Other models in the same series: | ||

| + | * [[Technics_RS-777]] | ||

| + | * [[Technics_RS-10A02]] | ||

| + | * [[Technics_RS-1500_US]] | ||

| + | * [[Technics_RS-1500_S4]] | ||

| + | * [[Technics_RS-1506_US]] | ||

| + | * [[Technics_RS-1700]] | ||

| + | * [[Technics_RS-1800]] | ||

| + | |||

| + | |||

| + | == Pictures == | ||

| + | [[Image:RS-1500.jpg]] | ||

| + | * Capstan and winding motor | ||

| + | [[Image:Rs-1500u-motor.jpg]] | ||

| + | * And here's another custom build by Nikola and Jozef. A digital tape counter with real time display for all three speeds (No conversion needed here). An absolutely perfect solution and an excellent work! To adapt the lettering, however, one would have to repaint the complete front plate and re-label it using silk-screen printing. After this modification, the squeaking drive disk of the old mechanical tape counter will never be an issue again. This counter can also be installed in a RS-1506 US or a RS-1700. If you want to know more about how it works and how to install it in a Technics, please have a look here: [http://forum2.magnetofon.de/board2-tonbandgeräte/board20-tipps-und-erkenntnisse/10204-echtzeit-bandzählwerk-für-alle-bandmaschinen/ real-time-counter-for-tape-machines]. | ||

| + | [[Image:Bandzaehlwerk.jpg]] | ||

| + | |||

| + | |||

| + | == Reports == | ||

| + | Here are a few repair reports on errors on the machine, with a request to add them if anyone has ever had problems with the unit: | ||

| + | |||

| + | * Instructions for disassembling and cleaning the switches: [http://www.tonbandhobby.de/rep-1506.htm switch-problems] | ||

| + | |||

| + | * Defect in the control of the winding motors. Recognizable by coils running unevenly or stopping. Possible cause see here: [http://forum2.magnetofon.de/board2-tonbandgeräte/board15-hilfe/1773-technics-1506/#post17804 Technics RS-1506US] and here: [http://forum.magnetofon.de/index.php?topic=1772.msg19918#msg19918 Technics RS-1506 US] | ||

| + | |||

| + | * IC Logic Control button control stops working. Possible cause see here: [http://www.siliconchip.com.au/cms/A_102669/article.html A real recorder] | ||

| + | |||

| + | And here are three more very informative reports from Oliver on Technics tape machines: | ||

| + | * '''Tips for buying a Technics RS tape recorder!"'' -by Oliver-. | ||

| + | For all those who have fallen for the dream of buying a Technics tape recorder, I would like to give a few tips along the way. | ||

| + | |||

| + | In principle, the Technics RS is a very robust machine which, under normal operating conditions and care, can put away its 20 years without major signs of wear. Unfortunately, however, this is not the normal case, and for this reason you should pay attention to a few things before buying and, if necessary, it is better to do without the purchase than to struggle unnecessarily with the tiresome procurement of spare parts! From my own experience and research I can say that worldwide at Matsushita/Technics no more spare parts are available and often a repair at Panasonic is rejected. | ||

| + | |||

| + | It should be mentioned in advance that the models RS-1500 and RS-1506 are technically and mechanically absolutely identical! The design as half- or quarter-track machine is only determined by the choice of the sound head carrier unit. So here the configuration can easily be changed by an additionally purchased head! | ||

| + | |||

| + | Unlike many other tape recorders, the heads on the RS are not the big weak point in terms of wear! (except for years of SHAMROCK attack!) Important when buying is to pay attention to whether the sound head adjustment screws have been subsequently changed. Usually easy to spot, as these black screws are located on the front of the headstock plate! Every improper change damages the heads and changes the sound characteristics. Even short runs with incorrect adjustment can cause damage. Correct adjustment can only be carried out at calibration stations! Never by ear! | ||

| + | |||

| + | Furthermore, the heads should be checked for heavy grinding, whereby the eraser head can be disregarded somewhat, since it consists only of ferrite and usually has grinding marks after only a few hours of operation. (lower left head). | ||

| + | |||

| + | Again and again the question is asked how deep the cut-in may be without loss of sound. Basically, the wider the head mirror (the surface rubbed off the tape), the deeper the cut-in. Even with a head mirror of 3 mm there is no loss of sound. It is important that the head mirror is rectangular and not trapezoidal. If it is trapezoidal, then either the head or the tape guide is misaligned. | ||

| + | |||

| + | Often oxidation at the selector switch for the track types can also be the cause of a channel failure! ...as well as the plug contacts of the head holder! Here a short treatment with [http://de.wikipedia.org/wiki/Ballistol Ballistol] helps. The smell of this spray oil reminds of unwashed socks, but it works wonders! This miracle product is available at Conrad-Elektronic or in any gun shop. | ||

| + | |||

| + | :Topic brakes: In 90% of the cases the brakes on Technics tape machines were never maintained by their owners. Consequence: ...after winding, the tape does not come to a stand on tension, but forms a loop, the idler pulleys go up and actuate a microswitch, which blocks the control functions. | ||

| + | |||

| + | The RS has two braking systems connected in series. An electronic brake and a mechanical shoe brake. The latter is the big weak point of all Technics RS belt machines. The pads are made of felt and wear out very quickly. A change of the pads is therefore pre-programmed! Unfortunately this process is very labour intensive. The entire mechanical area of the RS is covered by the electronics. The machines are modular, but often the individual boards are connected by long cable harnesses and difficult to remove! Caution! Old circuit boards have often become brittle over the years due to thermal stress! | ||

| + | |||

| + | Also the whole spring mechanism is often worn out after 15-20 years of operation! Mostly the springs are only held by the glue. The cause of the fault then shows up in the deflection rollers, which no longer go into the end position and switch off the motors after the belt has run out! Another indicator for old springs is the poor winding of the belt, because the tension readjustment no longer compensates. | ||

| + | |||

| + | :So before buying, it is worth removing the six screws at the back and taking a look at the heart of the unit. Often, after the first look inside, you immediately want to reach for the vacuum cleaner to remove the jumble of dust including dried spiders! Dust accumulation is certainly a serious cause of thermal and static damage over the years,....but also a small guarantee that this machine has not been fiddled with. | ||

| + | |||

| + | :Now how do I tell if the RS in front of me is a tinkerer's machine, or an untainted original part. Most repair jobs result in one of the many wiring harnesses coming loose 90% of the time. Technics did not use the standard IBM ties to bind the wiring harnesses, but their own thin ball chain shaped tie lashers! So if you come across any IBM ties, ....or even loose wiring harnesses, this is surely a sign of subsequent repair. Findings of insulating tape should trigger an alarm immediately. | ||

| + | |||

| + | The capstan shaft should be checked for absolute concentricity and should not make any noise! The belt plate axles should also have no "knock". Often you can hear knocking or clacking noises during belt standstill, especially with the more highly stressed capstan motor of the RS 1700. In play mode, where the pinch rollers are back against the capstan shaft, this noise disappears! Here the motor tells us silently but not quietly that its bearing is defective! | ||

| + | |||

| + | By the way, the pressure rollers should have a radius of at least 1.8 cm. Also the drive belts of the counter often become brittle and tear. Replacing them is also very tedious! | ||

| + | |||

| + | :Every now and then a marrow-shaking noise appears when rewinding. This is a sign of resinous lubrication of the flywheel of the counter drive! | ||

| + | |||

| + | :Changing a broken VU light is a pig's work and should be considered when negotiating a sale. Caution. All switches are special Technics designs and are difficult to replace with industry standard and install to fit the circuit board. | ||

| + | |||

| + | Well preserved Technics RS machines should be in the following price categories: TECHNICS RS-1500-1506 approx.: € 550.- to € 800.- (incl. original NAB adapter !) TECHNICS RS-1700 approx. : € 700 to € 1.100.- Remote (cable) ca.: € 130.-, Hood ca.: € 100.- to € 150.- Head unit (unused!) ca.: € 300.- to € 450.- Old machines can be recognized by the "NATIONAL-LOGO" in front of the writing "Technics". | ||

| + | |||

| + | Often Technics tape recorders are advertised in internet auctions as attic or cellar finds, which are said to have been hardly used or not used for years! Sounds good at first, .....man assumes to have found a little worn tape machine! But beware! Long storage times without use can be just as damaging for the electronics and various rubber parts! Especially the capacitors on the logic-board for the control functions tend to "dry out", if the machine stood around for years without power supply! The various rubber parts of the mechanics (e.g.: sleeves of the hydraulic damping, counter belts) have mostly become brittle due to the overlay. The entire lubricants of bearings and linkages have also become resinous over the years and thus block the smooth functionality of the tape machine. | ||

| + | |||

| + | :Also an examining look into the environment of the salesman often reveals whether he handles his belongings with care or not! Promotional sales slogans like: Cult machine, rarity, attic and basement find, bargain....etc. are rather synonymous with the dollars in the eye of the seller, less for a real HiFi collector! If you have any further questions, I'll be happy to help and advise! Greetings OLIVER | ||

| + | |||

| + | *'''Tips for the care of a Technics RS tape machine''' -by Oliver- | ||

| + | |||

| + | :Often there are small things that can prolong the life of a tape machine or counteract age-related material wear in time. | ||

| + | |||

| + | :I would like to start with the tape type selection! The tape heads of the Technics RS series are made of very durable Permaloy material, which under normal conditions offers a strong protection against the hard frictional forces of the tape material. The older a tape is, the way it is stored, and the frequency of use are all factors in the degradation of the backing layers! Tape material becomes brittle and hard over time. Detaching particles immediately clog the head gaps and cause significant sound degradation! But much worse is the effect of the hard carrier material. It literally mills the tone heads and destroys them in a short time by irreparable grinding. Even if the temptation is great, the price and the quantity still so favourable,....... never buy and use older tape material,..... You will only damage your sound heads and end up paying for it! Fresh tape not only ensures protection, but also the best sound recording. New and good tapes are available from [http://www.rmgi.nl/ RMG], for example the [http://www.rmgi.eu/pdf/RMGI_LPR_35.pdf LPR35]. | ||

| + | |||

| + | Cleaning of the sound heads, the deflection and pressure rollers, as well as the capstan shaft cylinder should be done at regular intervals or after intensive use! The best cleaning agent is spirit or isopropanol! Q-tips have a decisive advantage over leather strip sticks. No fine leather particles can come loose and rub into the clay head gaps. | ||

| + | |||

| + | To ensure smooth running of the deflection and pressure rollers, the respective axles can be smeared a little with fine roller grease. By turning off the conical head on the deflection rollers, the ball bearings can be pulled off and cleaned as well! Petrol bath! By the way, the ball bearings are industrial standard parts (605Z or 605ZZ) and therefore still available without any problems. When removing the pressure rollers, always pay attention to the number and layering of the washers, so that the reassembly is done in reverse order! The number of washers must be the same on both sides! Also make sure that no grease gets into the belt guide areas! Generally use it very sparingly!! | ||

| + | |||

| + | :Switches and knobs can be protected permanently if they are sprayed with "Ballistol". Ballistol has the advantage that a sliding lubrication is applied for cleaning. Contact spray dries out the conductors and destroys them in the long run. Cracking and scratching are audible consequences. | ||

| + | |||

| + | Two weak points of the Technics RS are located inside the machine. They are the very badly accessible rubber bands of the counter. Often they are worn out or they become brittle and tear. The smaller rubber can be replaced quite quickly if you unscrew the back cover. The larger rubber, which runs over the pulley, must be threaded through the gap at the pulley from the front if you do not want to remove the pulley. The removal of the pulley is relatively simple. To do this, you have to twist off the middle disc (has two small indentations) with a strong thumb pressure (it is best to put a disposable rubber in between). The ring around it is pulled out with the copper spring cross behind it. Now you only have to loosen the snap ring and can pull the pulley off the axle. With a little skill you can also use a Q-tip dabbed with Vaseline to lubricate the ribbons and preserve them supple. | ||

| + | |||

| + | :Where the rear panel of the unit is currently open, take the opportunity to carefully vacuum off any embedded dust! Avoid moving the circuit boards if possible. Boards become brittle over time and solder joints can pop off when the board is stretched! | ||

| + | |||

| + | :When the Technics RS tape machines came on the market, we had a voltage of 210-220V in Germany. In most cases the transformer should still be set to this voltage! Since a few years the voltage in the household network has been changed to 230V. Generally the transformer can cope with this small voltage increase. Nevertheless, I would recommend a changeover to 240V for older devices. Firstly, the transformer does not heat up so much and secondly, the electronic components are not driven to the load limit. The voltage changeover is done on the back of the device by turning the voltage selector switch to 240V. Please disconnect the device from the mains! | ||

| + | |||

| + | The tension springs should also be relieved after each playback of a tape! Often the play mode is simply stopped and the unit switched off. Then the tape machine often stands around for days with the deflection springs tightened and a tight tape. This puts unnecessary stress on the tape material and springs. Turn the two reels in opposite directions so that the tape relaxes and the deflection rollers move upwards! The belt now lies very loosely, the springs relax and thus last longer! | ||

| + | |||

| + | To repair minor damage to the paintwork, use BMW touch-up pencil, colour sable brown metallic no. 0196. | ||

| + | |||

| + | By the way, a hood really protects the tone heads and the tape from static flying dust!!! On ebay some are offered from time to time, unfortunately horrendous prices are offered for them in the meantime. Record: A Dutchman in the USA once offered almost 500 € for such a cover, and a few weeks ago such a cover was sold on ebay for about 300 €. Originally these hoods once cost 85 DM. When buying, it is important to make sure that the hood has no cracks, crazing or deep scratches and that the five rubber holders are still on. Scratches can be polished out with a special paste, if they are not too deep, see [http://www.xerapol.de/ Xerapol]. | ||

| + | |||

| + | *'''Tips for repairing Technics RS tape machines''' -by Oliver- | ||

| + | |||

| + | One of the most common problems with Technics RS tape machines is the loss of braking power, which occurs automatically after a certain age and wear phase. Depending on the tape quantity distribution of the two coils, the effect occurs at the beginning sometimes stronger, sometimes weaker. The result is usually that the belt plates are no longer braked strongly enough and the belt ultimately does not come to a stand on tension. A loop is formed underneath the deflection roller, the tape guide levers are released and actuate two small microswitches on the inside, which in turn switch off the operating buttons! Without manual rewinding of the spools, nothing will run anymore! You patiently go through this process two or three times and then the big hate begins! But self-healing never happens! But no reason to get the old Revox out of the cellar! (Their brake bands are certainly squeaking in the meantime). | ||

| + | |||

| + | If you want to know how the brakes of your machine are doing the following brake test: | ||

| + | |||

| + | :When the machine is switched off, the brake shoes are extended upwards and press on the winding motor, therefore the motors must not turn freely by hand, but you must feel resistance when turning. With the right-hand spool clockwise a little more than anticlockwise. With the left coil it is the other way round. | ||

| + | |||

| + | :To test the brakes on the left winding motor, proceed as follows: Tension the tape with the full spool sitting on the left winding motor. Now press fast forward and wait a few seconds for the motors to reach full speed. Then press the play button. The left coil, which is still almost full and therefore very heavy, must now be braked very hard. If the brakes are down, this spool will spin too fast and a loop will form underneath the pulley, causing the controller to switch off. To test the brakes of the right winding motor, exchange the coils and use the fast return. | ||

| + | |||

| + | The brakes can also be adjusted by loosening the two screws on the brake plunger and moving the whole brake mechanism up or down a little (see photo). | ||

| + | |||

| + | :Let's start a repair attempt !!! The Technics RS tape machines have two braking systems connected in series. An electronic brake and a mechanical shoe brake. The brake shoes were fitted at the factory with felt material as a support material. Now, after a few years of use, the felt is of course rubbed smooth! | ||

| + | |||

| + | To get to the brake shoes you have to remove the two winding motors! The brakes have an external pressure surface, over which they deliver their braking force on the drum cylinder of the winding motors. To get access to the 3 screws of the motors it is recommended to remove the transformer/remote unit! Remove the rear housing strut! If you have now unscrewed the motors from the cast plate, you can now see the brake mechanism including brake shoes on the underside! | ||

| + | |||

| + | :[[Picture: Brake shoes2b.jpg]] | ||

| + | |||

| + | :The small plastic shoes can be pulled off via a snap ring and a small washer! Pulling off the snap ring and pushing it back on is a tricky business, because it is very small and falls off very quickly and then lands somewhere in the machine. To be on the safe side, you can tie it with twine beforehand, then you can find it again without a long search. When the snap ring and the disc are down, loosen the two adjusting screws, to which the brake mechanism is fastened on the front plate, so far that you can tilt the whole brake mechanism a little bit to the back. Now the brake shoes can be pulled forward out of the recess for the winding motors. | ||

| + | |||

| + | :All the old brown felt covering must be carefully removed. Roughen the bearing surface a little afterwards! Now you can get identical felt material and replace it, but much more effective and durable is leather as a brake pad. I have used it on all my tape machines and they brake excellently, even after 2 years of continuous use! An alternative would be to use cork instead of felt, but I can't say if that works, because I've never tried it with cork (Jeff Jacobs uses cork : [http://www.j-corder.com/The_Restoration_Process.php J-corder] ). Rubber as a brake pad is totally unsuitable, as the brakes then start to rattle at a certain rpm. So, let's give our RS an ABS system and use leather!!! The thickness of the leather is between 1 and 1.5 mm, depending on how much play the individual brake mechanism has! I wouldn't use chamois as it is too thin and will disintegrate with constant use. | ||

| + | |||

| + | It is imperative that the cut-to-size leather coverings are fixed with 2-component adhesive, e.g. [http://www.uhu.de/produkte/2-komponenten-klebstoffe.html?tx_uhuproductview_pi1%5BproductId%5D=14&cHash=2816d308d7&step=0 UHU plus endfest 300]. It is essential to allow the adhesive to cure fully, do not underestimate the braking forces that occur!!! Clean the drum cylinders of the winding motors briefly with petrol and the assembly can begin! CAUTION! The first braking attempts should be made at very slow speed! Initially there could be too much braking force, which can have enormous pulling effects. It may be necessary to readjust the brakes at the two screws of the brake plunger. If this is not sufficient, the leather thickness must be reduced! If the braking is weak, use thicker leather! After that the brakes should be fit again for the next years! | ||

| + | |||

| + | Good luck, OLIVER | ||

| + | |||

| + | |||

| + | *'''Wooden side panel for the Technics tape machines RS 1500US, RS 1506US and RS 1700 (Attention! Not for the RS-1520!)''' | ||

| + | :-from Michael- | ||

| + | |||

| + | :Usually the Technics tape machines have black side panels. However, in the American market, machines were sold that had wooden side panels. In Germany, these side panels were available as accessories from about 1982 under the accessory designation RP-9120. These side panels are made of veneered wood. This is probably Rio rosewood, a tropical precious wood, whose trade was forbidden in the 60's. However, this wood is still available as veneer. However, this wood is still available as veneer and is used in guitar making, among other things. | ||

| + | |||

| + | If you want to build these side panels yourself, you can find the measurements of the original panels below. Suitable woods are 3 cm thick boards of knotless oak, cherry or maple, with a flat grain (so-called horizontal annual rings). The most similar to the original is American oak (red oak), which is more coarse-grained than European oak. I therefore recommend to visit a carpenter's workshop (wood of this thickness must be stored for at least 5, preferably 15 years, so that it does not crack later, no DIY store has this!) | ||

| + | Mahogany stain (No. 2529) from Clou is suitable (available in almost every DIY store). The stain should be applied twice and, after light sanding, painted over with a silk-matt clear varnish. The stained side parts have a slight reddish tinge and look very similar to the originals. On the picture you can see the originals on the left and the stained and varnished oak boards on the right. | ||

| + | |||

| + | The boards are screwed on and the front edges are rounded with a radius of about 4 mm. Here are the dimensions of the hole for the original screws (lens head, cross recess, M 4, L = 30 mm): hole at the top with d = 10 mm and 8 mm depth, then tapered to d = 8 mm with 22 mm depth. If the original screws of the old black cover are to be used again (M 4, length 14 mm), the 10 mm hole must be set correspondingly deeper (24 mm instead of 8 mm). Pay attention to the exact hole spacing, the dimensions given always refer to the centre of the hole. | ||

| + | [[Picture: Panel.jpg]] | ||

| + | [[Picture: Panel2.jpg]] | ||

| + | [[Picture: Panel3.jpg]] | ||

| + | |||

== Links == | == Links == | ||

| + | * Promotional brochure for the Technics RS-1700, RS1506US and RS-1500US as a pdf file in color: [http://www.gromit.dk/technics/rs-1500us.pdf Technics RS-1700, RS1506, RS-1500] | ||

| + | * Operating Instructions (free pdf file): [http://www.audiofriends.nl/technics/Technics%20RS-15001506%20Operating%20Instructions%20(Complete).pdf Technics Tape Deck RS-1500 RS-1506 Operating Instructions] | ||

| + | * Test report RS-1500 against Uher SG639 Logic [http://tonbandwelt.magnetofon.de/jahrb/fonoforum/04.htm FonoForum Heft 12/1977] | ||

| + | * Test Report RS-1500 [http://tonbandwelt.magnetofon.de/jahrb/150078/technics.htm HiFi-Stereophonie Heft 9/1978] | ||

| + | * Test report RS-1500 [http://tonbandwelt.magnetofon.de/jahrb/stp_1980/stplay.htm stereoplay Heft 12/1980 tape machine test] | ||

| + | * Test report in English [http://mpbarney.googlepages.com/PanasonicRS-1500ReviewAudioMay1977.pdf Audio Magazine May 1977] | ||

| + | * [http://wegavision.pytalhost.com/technicsRS1500Up special brochure RS-1500US] | ||

| + | * Technics RS tape machines and accessories: [http://www.thevintageknob.org/technics-RS-1500U.html The Vintage Knob] | ||

| + | * Silver RS-1700: [http://my.reset.jp/%7Einu/ProductsDataBase/Products/Technics/Isolated_Open_Deck/Isolated%20Loop%20Open%20Deck.htm Japanese Page] | ||

| + | * [http://galerie1.magnetofon.de/categories.php?cat_id=6 Oliver's Technics Tape Machine Collection] | ||

| + | * There's no accounting for taste, at least the Black Magic doesn't look that bad [http://www.j-corder.com/Black_Magic.html Modified Technics tape machines] Silver plating the entire front panel of an RS-1700 is said to cost just under $1000. | ||

| − | + | [[Category:Tape machines]] | |

| − | [[ | ||

Latest revision as of 09:20, 12 May 2020

Data

General

- Manufacturer: Technics

- Model: RS-1500US

- Years of manufacture: 1976 to 1986

- Made in: Osaka, Japan

- Color: black

- Remote control: optional with RP-9690 (wired remote control) or RP-070 (infrared remote control)

- Power consumption: 120 W

- Dimensions: Width:456 mm, Height: 446 mm, Depth: 258 mm.

- Weight: approx. 25 kg

- Original price approx.: 2,630 DM to 3,000 DM

Option 2-track headstock RP-2224: 399 DM Option 4-track headstock RP-2422: 399 DM

Connections

- Number of outputs: 2

- Headphones: 80 mV/8Ohm

Line Out: 0.5 V (OVU)/at 22 kOhm or more

- DIN: No

- Number of inputs: 3

- Microphone: 0.25 mV (-72 dB)/4.7 kOhm

- Line In: 60 mV (-24 dB)/150 kOhm

- Trough Out: 60 mV (-24 dB)/150 kOhm

Technical Data

max.coil diameter: 26,5 cm

Drive: Direct-drive, brushless DC motor with phase-locked quartz control for the tone shaft (from turntable e.g. 1210), two direct-drive, brushless DC motors with tape tension control for the winding plates

- Heads: 4 tone heads (head carrier: RP-2224)

- Tracks: 2-track, 2-channel stereo record/playback and 4-track, 2-channel stereo playback

- Tape speeds: 9.5 cm/s, 19 cm/s and 38 cm/s

- Slip:

- at 9.5 cm/s: 0.018% (WRMS) +/-0.035% DIN)

- at 19 cm/s: 0.03% (WRMS) +/-0.06% DIN)

- at 38 cm/s: 0.06% (WRMS) +/-0.12% DIN)

- Pitch fluctuations:

- Overall frequency response:

- at 9.5 cm/s: 20 - 15,000 Hz, +/-3 dB

- at 19 cm/s: 20 - 25,000 Hz, +/-3 dB

- at 38 cm/s: 30 - 30,000 Hz, +/-3 dB

- Signal-to-noise ratio:

- extraneous signal-to-noise ratio (pickup level = 3% total harmonic distortion):

- at 9.5 cm/s: 66 dB

- at 19 cm/s: 68 dB

at 38 cm/s: 68 dB

- Total harmonic distortion (0 VU): 0.8%

- crosstalk fluctuation (38 cm/s): 0.05%

- Crosstalk attenuation at 1 kHZ in stereo mode: 50 dB

- Cancellation attenuation: at 19 cm/s: 65 dB

- Premagnetization and extinction frequency: 120 kHz

Special Features

- Speed fine adjustment (record/playback): +/-6%.

- Four-digit tape counter, at 38 cm/s display of real time, at other tape speeds must be converted.

- "Isolated Loop" tape guide

Accessories (for pictures see RS-1506US and RS-1700)

- RP-9100 flight case (1)

- RP-9110 Hard plastic dust cover to put on when coils are mounted (2)

- RP-9120 Wooden side panels (Rio rosewood, veneered, thickness of side panels: 3 cm)

- RP-9130 Brackets for shelf mounting (3)

- RP-9690 Cable remote control for RS-1500US and RS-1506US (4)

- RP-9170 Cable remote control for RS-1700

- RP-070 Infrared remote control with receiver and transmitter (see RS-1700)

- RP-10A 26.5 cm aluminium empty reel (5)

- RP-2422 quarter-track headstock (7)

- RP-086 Battery adapter for 24 V DC operation

Remarks

- The machine is not EE tape compatible!

- Technically, the machine is identical to the RS-1506US. Audio head carrier on the RS-1500US is the RP-2224 (2-track record playback/4-track playback). On the RS-1506US, the audio head mount is the RP-2422 (4-track record/playback/2-track playback). Both headstocks can be interchanged at will between the two machines by loosening three screws. The RP-2224 and RP2422 headstocks also work on a RS-1700, but here the autoreverse function is switched off.

Typical signs of age:

- Worn brake pads. The felt pads on the rewind motor brakes are usually worn and the tape throws loops when you switch from rewind mode to play mode. The looping causes the key control to shut down and cannot be used again until the tape is retightened. You can remedy this by replacing the old felt brake pads with suede. How to do this is described in detail at [Tips for repairing Technics RS tape machines].

- Belt counter drive squeal. The drive pulley of the tape counter belt causes loud squeaking noises when rewinding. These squeaking noises disappear if you oil the axle of this drive pulley.

Worn out springs. If the machine has been standing around for years with the belt tensioned, the springs of the deflection pulleys are worn out. The machine will then no longer switch off when the belt has been unwound, as the deflection pulleys are no longer pulled completely upwards. The only remedy is to replace the springs. In the black plastic caps of the toggle switches for monitor, tape select and rec mode there are small metal springs to push on and fix the caps. Over the years, the plastic becomes brittle and bursts, causing the springs to push the plastic apart and the caps to fall off. Burst plastic caps can be repaired by gluing them together with 2-component glue and then putting tight black heat shrink tubing over them and heating it with hot air. Without the shrink hose, the glued plastic caps will not hold in the long run, no matter which glue you use. As a replacement for the plastic caps, you can also use aluminum caps from old Pioneer units (SA-XXXX or SX-XXXX) that fit on the switch tabs. See Image: SA-300K.

- Spare parts and accessories are no longer available from Panasonic or Technics.

- The AC power supply of the European version is switchable from 220V/240V to 110V/125V 50/60Hz. The American version is only designed for 110V/125V, but can also be operated on 220V/240V mains via an external transformer (so-called stepdown converter). The only important thing about such a converter is that it can handle the power consumption of the machine.

- Sending such a machine is a very delicate matter due to its heavy weight, as postal or parcel services are not exactly squeamish about such packages. I therefore recommend a personal delivery, even if you have to drive a few kilometers. Well packed, the Technics will even survive a trip across the pond. However, it is necessary to cover the front, back and sides with sufficiently thick polystyrene sheets. If the machine is only wrapped in crumpled up newspapers and styrofoam chips, the feet of the back or bottom panel or the switches, knobs or even the headstock on the front will inevitably punch into the machine when the package is thrown somewhere.

- Matching equipment from Technics:

- Other models in the same series:

- Technics_RS-777

- Technics_RS-10A02

- Technics_RS-1500_US

- Technics_RS-1500_S4

- Technics_RS-1506_US

- Technics_RS-1700

- Technics_RS-1800

Pictures

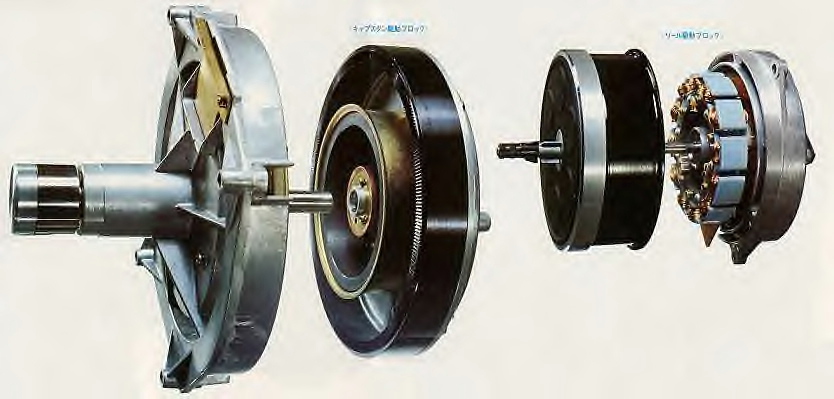

- Capstan and winding motor

- And here's another custom build by Nikola and Jozef. A digital tape counter with real time display for all three speeds (No conversion needed here). An absolutely perfect solution and an excellent work! To adapt the lettering, however, one would have to repaint the complete front plate and re-label it using silk-screen printing. After this modification, the squeaking drive disk of the old mechanical tape counter will never be an issue again. This counter can also be installed in a RS-1506 US or a RS-1700. If you want to know more about how it works and how to install it in a Technics, please have a look here: real-time-counter-for-tape-machines.

Reports

Here are a few repair reports on errors on the machine, with a request to add them if anyone has ever had problems with the unit:

- Instructions for disassembling and cleaning the switches: switch-problems

- Defect in the control of the winding motors. Recognizable by coils running unevenly or stopping. Possible cause see here: Technics RS-1506US and here: Technics RS-1506 US

- IC Logic Control button control stops working. Possible cause see here: A real recorder

And here are three more very informative reports from Oliver on Technics tape machines:

- 'Tips for buying a Technics RS tape recorder!" -by Oliver-.

For all those who have fallen for the dream of buying a Technics tape recorder, I would like to give a few tips along the way.

In principle, the Technics RS is a very robust machine which, under normal operating conditions and care, can put away its 20 years without major signs of wear. Unfortunately, however, this is not the normal case, and for this reason you should pay attention to a few things before buying and, if necessary, it is better to do without the purchase than to struggle unnecessarily with the tiresome procurement of spare parts! From my own experience and research I can say that worldwide at Matsushita/Technics no more spare parts are available and often a repair at Panasonic is rejected.

It should be mentioned in advance that the models RS-1500 and RS-1506 are technically and mechanically absolutely identical! The design as half- or quarter-track machine is only determined by the choice of the sound head carrier unit. So here the configuration can easily be changed by an additionally purchased head!

Unlike many other tape recorders, the heads on the RS are not the big weak point in terms of wear! (except for years of SHAMROCK attack!) Important when buying is to pay attention to whether the sound head adjustment screws have been subsequently changed. Usually easy to spot, as these black screws are located on the front of the headstock plate! Every improper change damages the heads and changes the sound characteristics. Even short runs with incorrect adjustment can cause damage. Correct adjustment can only be carried out at calibration stations! Never by ear!

Furthermore, the heads should be checked for heavy grinding, whereby the eraser head can be disregarded somewhat, since it consists only of ferrite and usually has grinding marks after only a few hours of operation. (lower left head).

Again and again the question is asked how deep the cut-in may be without loss of sound. Basically, the wider the head mirror (the surface rubbed off the tape), the deeper the cut-in. Even with a head mirror of 3 mm there is no loss of sound. It is important that the head mirror is rectangular and not trapezoidal. If it is trapezoidal, then either the head or the tape guide is misaligned.

Often oxidation at the selector switch for the track types can also be the cause of a channel failure! ...as well as the plug contacts of the head holder! Here a short treatment with Ballistol helps. The smell of this spray oil reminds of unwashed socks, but it works wonders! This miracle product is available at Conrad-Elektronic or in any gun shop.

- Topic brakes: In 90% of the cases the brakes on Technics tape machines were never maintained by their owners. Consequence: ...after winding, the tape does not come to a stand on tension, but forms a loop, the idler pulleys go up and actuate a microswitch, which blocks the control functions.

The RS has two braking systems connected in series. An electronic brake and a mechanical shoe brake. The latter is the big weak point of all Technics RS belt machines. The pads are made of felt and wear out very quickly. A change of the pads is therefore pre-programmed! Unfortunately this process is very labour intensive. The entire mechanical area of the RS is covered by the electronics. The machines are modular, but often the individual boards are connected by long cable harnesses and difficult to remove! Caution! Old circuit boards have often become brittle over the years due to thermal stress!

Also the whole spring mechanism is often worn out after 15-20 years of operation! Mostly the springs are only held by the glue. The cause of the fault then shows up in the deflection rollers, which no longer go into the end position and switch off the motors after the belt has run out! Another indicator for old springs is the poor winding of the belt, because the tension readjustment no longer compensates.

- So before buying, it is worth removing the six screws at the back and taking a look at the heart of the unit. Often, after the first look inside, you immediately want to reach for the vacuum cleaner to remove the jumble of dust including dried spiders! Dust accumulation is certainly a serious cause of thermal and static damage over the years,....but also a small guarantee that this machine has not been fiddled with.

- Now how do I tell if the RS in front of me is a tinkerer's machine, or an untainted original part. Most repair jobs result in one of the many wiring harnesses coming loose 90% of the time. Technics did not use the standard IBM ties to bind the wiring harnesses, but their own thin ball chain shaped tie lashers! So if you come across any IBM ties, ....or even loose wiring harnesses, this is surely a sign of subsequent repair. Findings of insulating tape should trigger an alarm immediately.

The capstan shaft should be checked for absolute concentricity and should not make any noise! The belt plate axles should also have no "knock". Often you can hear knocking or clacking noises during belt standstill, especially with the more highly stressed capstan motor of the RS 1700. In play mode, where the pinch rollers are back against the capstan shaft, this noise disappears! Here the motor tells us silently but not quietly that its bearing is defective!

By the way, the pressure rollers should have a radius of at least 1.8 cm. Also the drive belts of the counter often become brittle and tear. Replacing them is also very tedious!

- Every now and then a marrow-shaking noise appears when rewinding. This is a sign of resinous lubrication of the flywheel of the counter drive!

- Changing a broken VU light is a pig's work and should be considered when negotiating a sale. Caution. All switches are special Technics designs and are difficult to replace with industry standard and install to fit the circuit board.

Well preserved Technics RS machines should be in the following price categories: TECHNICS RS-1500-1506 approx.: € 550.- to € 800.- (incl. original NAB adapter !) TECHNICS RS-1700 approx. : € 700 to € 1.100.- Remote (cable) ca.: € 130.-, Hood ca.: € 100.- to € 150.- Head unit (unused!) ca.: € 300.- to € 450.- Old machines can be recognized by the "NATIONAL-LOGO" in front of the writing "Technics".

Often Technics tape recorders are advertised in internet auctions as attic or cellar finds, which are said to have been hardly used or not used for years! Sounds good at first, .....man assumes to have found a little worn tape machine! But beware! Long storage times without use can be just as damaging for the electronics and various rubber parts! Especially the capacitors on the logic-board for the control functions tend to "dry out", if the machine stood around for years without power supply! The various rubber parts of the mechanics (e.g.: sleeves of the hydraulic damping, counter belts) have mostly become brittle due to the overlay. The entire lubricants of bearings and linkages have also become resinous over the years and thus block the smooth functionality of the tape machine.

- Also an examining look into the environment of the salesman often reveals whether he handles his belongings with care or not! Promotional sales slogans like: Cult machine, rarity, attic and basement find, bargain....etc. are rather synonymous with the dollars in the eye of the seller, less for a real HiFi collector! If you have any further questions, I'll be happy to help and advise! Greetings OLIVER

- Tips for the care of a Technics RS tape machine -by Oliver-

- Often there are small things that can prolong the life of a tape machine or counteract age-related material wear in time.

- I would like to start with the tape type selection! The tape heads of the Technics RS series are made of very durable Permaloy material, which under normal conditions offers a strong protection against the hard frictional forces of the tape material. The older a tape is, the way it is stored, and the frequency of use are all factors in the degradation of the backing layers! Tape material becomes brittle and hard over time. Detaching particles immediately clog the head gaps and cause significant sound degradation! But much worse is the effect of the hard carrier material. It literally mills the tone heads and destroys them in a short time by irreparable grinding. Even if the temptation is great, the price and the quantity still so favourable,....... never buy and use older tape material,..... You will only damage your sound heads and end up paying for it! Fresh tape not only ensures protection, but also the best sound recording. New and good tapes are available from RMG, for example the LPR35.

Cleaning of the sound heads, the deflection and pressure rollers, as well as the capstan shaft cylinder should be done at regular intervals or after intensive use! The best cleaning agent is spirit or isopropanol! Q-tips have a decisive advantage over leather strip sticks. No fine leather particles can come loose and rub into the clay head gaps.

To ensure smooth running of the deflection and pressure rollers, the respective axles can be smeared a little with fine roller grease. By turning off the conical head on the deflection rollers, the ball bearings can be pulled off and cleaned as well! Petrol bath! By the way, the ball bearings are industrial standard parts (605Z or 605ZZ) and therefore still available without any problems. When removing the pressure rollers, always pay attention to the number and layering of the washers, so that the reassembly is done in reverse order! The number of washers must be the same on both sides! Also make sure that no grease gets into the belt guide areas! Generally use it very sparingly!!

- Switches and knobs can be protected permanently if they are sprayed with "Ballistol". Ballistol has the advantage that a sliding lubrication is applied for cleaning. Contact spray dries out the conductors and destroys them in the long run. Cracking and scratching are audible consequences.

Two weak points of the Technics RS are located inside the machine. They are the very badly accessible rubber bands of the counter. Often they are worn out or they become brittle and tear. The smaller rubber can be replaced quite quickly if you unscrew the back cover. The larger rubber, which runs over the pulley, must be threaded through the gap at the pulley from the front if you do not want to remove the pulley. The removal of the pulley is relatively simple. To do this, you have to twist off the middle disc (has two small indentations) with a strong thumb pressure (it is best to put a disposable rubber in between). The ring around it is pulled out with the copper spring cross behind it. Now you only have to loosen the snap ring and can pull the pulley off the axle. With a little skill you can also use a Q-tip dabbed with Vaseline to lubricate the ribbons and preserve them supple.

- Where the rear panel of the unit is currently open, take the opportunity to carefully vacuum off any embedded dust! Avoid moving the circuit boards if possible. Boards become brittle over time and solder joints can pop off when the board is stretched!

- When the Technics RS tape machines came on the market, we had a voltage of 210-220V in Germany. In most cases the transformer should still be set to this voltage! Since a few years the voltage in the household network has been changed to 230V. Generally the transformer can cope with this small voltage increase. Nevertheless, I would recommend a changeover to 240V for older devices. Firstly, the transformer does not heat up so much and secondly, the electronic components are not driven to the load limit. The voltage changeover is done on the back of the device by turning the voltage selector switch to 240V. Please disconnect the device from the mains!

The tension springs should also be relieved after each playback of a tape! Often the play mode is simply stopped and the unit switched off. Then the tape machine often stands around for days with the deflection springs tightened and a tight tape. This puts unnecessary stress on the tape material and springs. Turn the two reels in opposite directions so that the tape relaxes and the deflection rollers move upwards! The belt now lies very loosely, the springs relax and thus last longer!

To repair minor damage to the paintwork, use BMW touch-up pencil, colour sable brown metallic no. 0196.

By the way, a hood really protects the tone heads and the tape from static flying dust!!! On ebay some are offered from time to time, unfortunately horrendous prices are offered for them in the meantime. Record: A Dutchman in the USA once offered almost 500 € for such a cover, and a few weeks ago such a cover was sold on ebay for about 300 €. Originally these hoods once cost 85 DM. When buying, it is important to make sure that the hood has no cracks, crazing or deep scratches and that the five rubber holders are still on. Scratches can be polished out with a special paste, if they are not too deep, see Xerapol.

- Tips for repairing Technics RS tape machines -by Oliver-

One of the most common problems with Technics RS tape machines is the loss of braking power, which occurs automatically after a certain age and wear phase. Depending on the tape quantity distribution of the two coils, the effect occurs at the beginning sometimes stronger, sometimes weaker. The result is usually that the belt plates are no longer braked strongly enough and the belt ultimately does not come to a stand on tension. A loop is formed underneath the deflection roller, the tape guide levers are released and actuate two small microswitches on the inside, which in turn switch off the operating buttons! Without manual rewinding of the spools, nothing will run anymore! You patiently go through this process two or three times and then the big hate begins! But self-healing never happens! But no reason to get the old Revox out of the cellar! (Their brake bands are certainly squeaking in the meantime).

If you want to know how the brakes of your machine are doing the following brake test:

- When the machine is switched off, the brake shoes are extended upwards and press on the winding motor, therefore the motors must not turn freely by hand, but you must feel resistance when turning. With the right-hand spool clockwise a little more than anticlockwise. With the left coil it is the other way round.

- To test the brakes on the left winding motor, proceed as follows: Tension the tape with the full spool sitting on the left winding motor. Now press fast forward and wait a few seconds for the motors to reach full speed. Then press the play button. The left coil, which is still almost full and therefore very heavy, must now be braked very hard. If the brakes are down, this spool will spin too fast and a loop will form underneath the pulley, causing the controller to switch off. To test the brakes of the right winding motor, exchange the coils and use the fast return.

The brakes can also be adjusted by loosening the two screws on the brake plunger and moving the whole brake mechanism up or down a little (see photo).

- Let's start a repair attempt !!! The Technics RS tape machines have two braking systems connected in series. An electronic brake and a mechanical shoe brake. The brake shoes were fitted at the factory with felt material as a support material. Now, after a few years of use, the felt is of course rubbed smooth!

To get to the brake shoes you have to remove the two winding motors! The brakes have an external pressure surface, over which they deliver their braking force on the drum cylinder of the winding motors. To get access to the 3 screws of the motors it is recommended to remove the transformer/remote unit! Remove the rear housing strut! If you have now unscrewed the motors from the cast plate, you can now see the brake mechanism including brake shoes on the underside!

- The small plastic shoes can be pulled off via a snap ring and a small washer! Pulling off the snap ring and pushing it back on is a tricky business, because it is very small and falls off very quickly and then lands somewhere in the machine. To be on the safe side, you can tie it with twine beforehand, then you can find it again without a long search. When the snap ring and the disc are down, loosen the two adjusting screws, to which the brake mechanism is fastened on the front plate, so far that you can tilt the whole brake mechanism a little bit to the back. Now the brake shoes can be pulled forward out of the recess for the winding motors.

- All the old brown felt covering must be carefully removed. Roughen the bearing surface a little afterwards! Now you can get identical felt material and replace it, but much more effective and durable is leather as a brake pad. I have used it on all my tape machines and they brake excellently, even after 2 years of continuous use! An alternative would be to use cork instead of felt, but I can't say if that works, because I've never tried it with cork (Jeff Jacobs uses cork : J-corder ). Rubber as a brake pad is totally unsuitable, as the brakes then start to rattle at a certain rpm. So, let's give our RS an ABS system and use leather!!! The thickness of the leather is between 1 and 1.5 mm, depending on how much play the individual brake mechanism has! I wouldn't use chamois as it is too thin and will disintegrate with constant use.

It is imperative that the cut-to-size leather coverings are fixed with 2-component adhesive, e.g. UHU plus endfest 300. It is essential to allow the adhesive to cure fully, do not underestimate the braking forces that occur!!! Clean the drum cylinders of the winding motors briefly with petrol and the assembly can begin! CAUTION! The first braking attempts should be made at very slow speed! Initially there could be too much braking force, which can have enormous pulling effects. It may be necessary to readjust the brakes at the two screws of the brake plunger. If this is not sufficient, the leather thickness must be reduced! If the braking is weak, use thicker leather! After that the brakes should be fit again for the next years!

Good luck, OLIVER

- Wooden side panel for the Technics tape machines RS 1500US, RS 1506US and RS 1700 (Attention! Not for the RS-1520!)

- -from Michael-

- Usually the Technics tape machines have black side panels. However, in the American market, machines were sold that had wooden side panels. In Germany, these side panels were available as accessories from about 1982 under the accessory designation RP-9120. These side panels are made of veneered wood. This is probably Rio rosewood, a tropical precious wood, whose trade was forbidden in the 60's. However, this wood is still available as veneer. However, this wood is still available as veneer and is used in guitar making, among other things.

If you want to build these side panels yourself, you can find the measurements of the original panels below. Suitable woods are 3 cm thick boards of knotless oak, cherry or maple, with a flat grain (so-called horizontal annual rings). The most similar to the original is American oak (red oak), which is more coarse-grained than European oak. I therefore recommend to visit a carpenter's workshop (wood of this thickness must be stored for at least 5, preferably 15 years, so that it does not crack later, no DIY store has this!) Mahogany stain (No. 2529) from Clou is suitable (available in almost every DIY store). The stain should be applied twice and, after light sanding, painted over with a silk-matt clear varnish. The stained side parts have a slight reddish tinge and look very similar to the originals. On the picture you can see the originals on the left and the stained and varnished oak boards on the right.

The boards are screwed on and the front edges are rounded with a radius of about 4 mm. Here are the dimensions of the hole for the original screws (lens head, cross recess, M 4, L = 30 mm): hole at the top with d = 10 mm and 8 mm depth, then tapered to d = 8 mm with 22 mm depth. If the original screws of the old black cover are to be used again (M 4, length 14 mm), the 10 mm hole must be set correspondingly deeper (24 mm instead of 8 mm). Pay attention to the exact hole spacing, the dimensions given always refer to the centre of the hole. Picture: Panel.jpg Picture: Panel2.jpg Picture: Panel3.jpg

Links

- Promotional brochure for the Technics RS-1700, RS1506US and RS-1500US as a pdf file in color: Technics RS-1700, RS1506, RS-1500

- Operating Instructions (free pdf file): Technics Tape Deck RS-1500 RS-1506 Operating Instructions

- Test report RS-1500 against Uher SG639 Logic FonoForum Heft 12/1977

- Test Report RS-1500 HiFi-Stereophonie Heft 9/1978

- Test report RS-1500 stereoplay Heft 12/1980 tape machine test

- Test report in English Audio Magazine May 1977

- special brochure RS-1500US

- Technics RS tape machines and accessories: The Vintage Knob

- Silver RS-1700: Japanese Page

- Oliver's Technics Tape Machine Collection

- There's no accounting for taste, at least the Black Magic doesn't look that bad Modified Technics tape machines Silver plating the entire front panel of an RS-1700 is said to cost just under $1000.