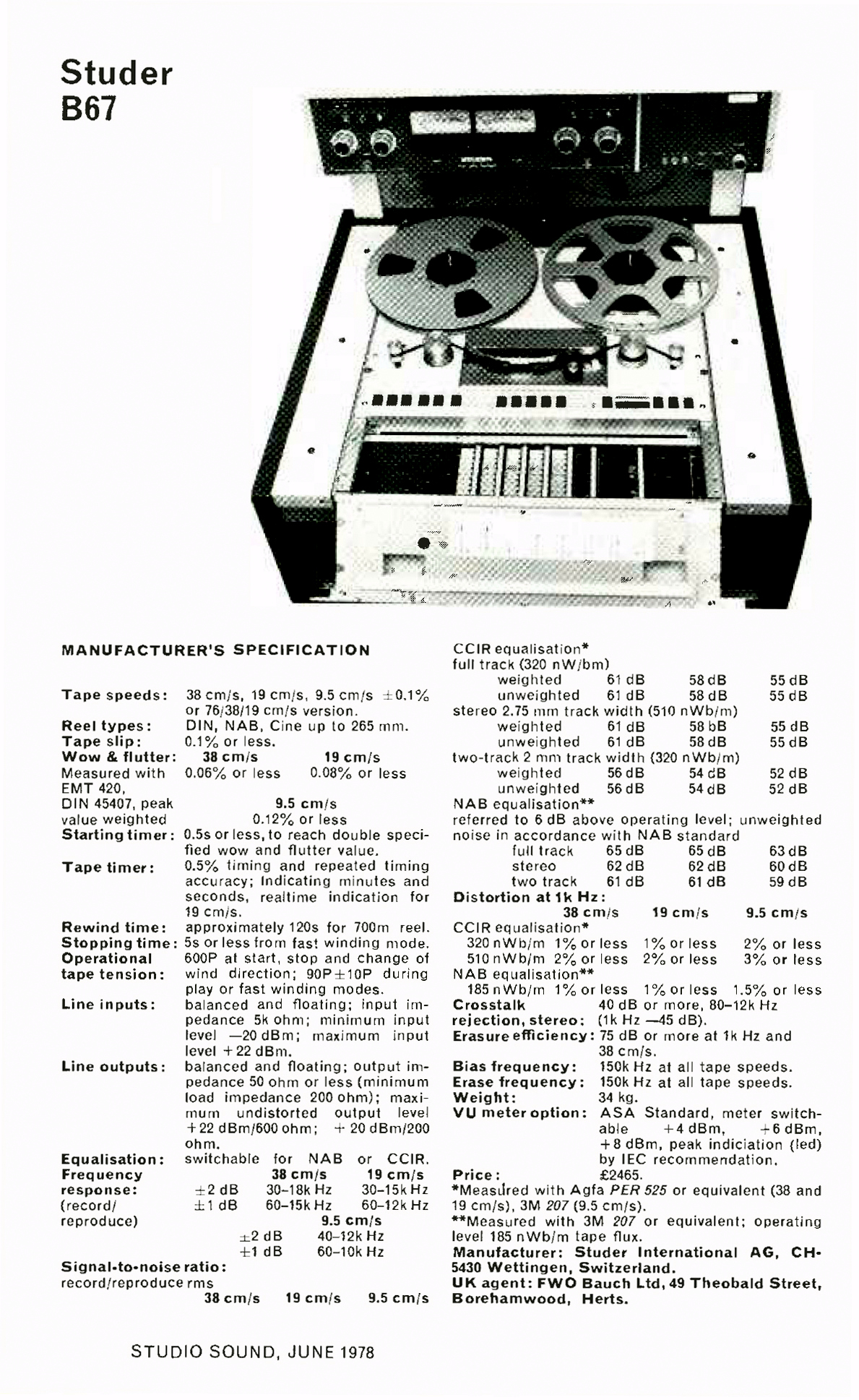

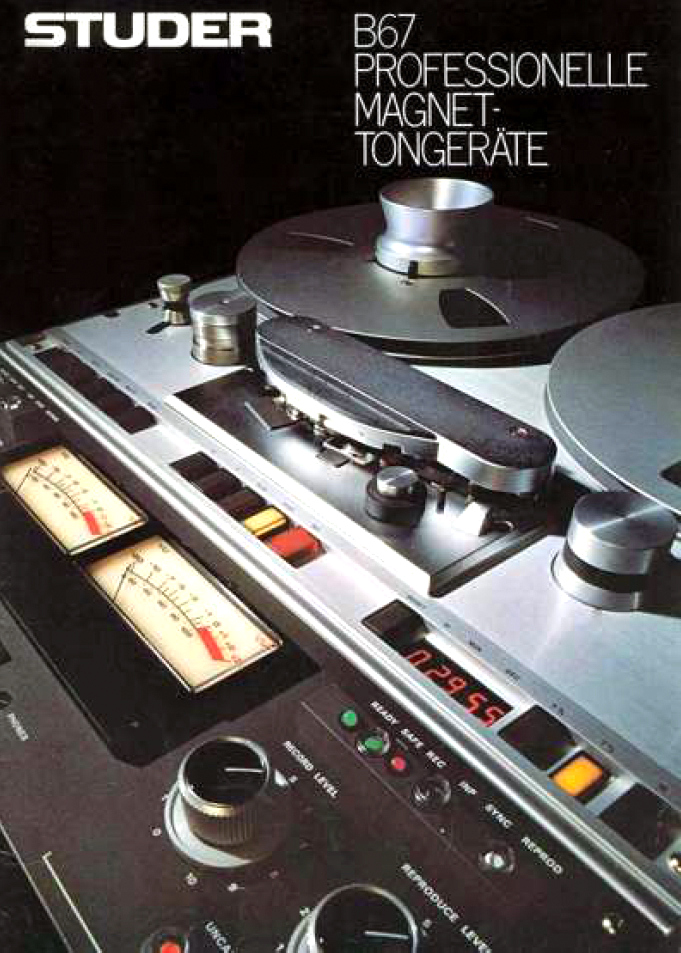

Studer B67

Data

General

- Manufacturer: Studer

- Model: B67

- Type: Professional tape machine

- Years of manufacture: 1978 - 1981

- Made in: Switzerland

- Color: Silver / Grey

- Original price approx.: from 7'000 DM

Technical data

Remarks

- Other models in the same series:

- Studer A62

- Studer A67

- Studer B30

- Studer B37

- Studer B62

- Studer B67

- Studer B67 II

Pictures

- Extract from brochure: Studer B67

Reports

- With the STUDER B67, a new series of tape machines was developed alongside the A67, based on the drive of the ReVox A700. The professional tape machine STUDER B67, B67 MK II, which was built in the period from 1975 to 1989 mainly for mobile use in OB vans and studios. The exceptionally robust and service-friendly tape machine has three tape speeds, a VU meter unit according to NAB standard, an electronic real value counter and can take reels up to 28.5 cm. As is usual with STUDER, the audio boards of the STUDER B67 are designed as plug-in printed circuit boards. The tape tension control, which was a completely new design at the time, is accessible from the front after opening the control panel, as are the amplifier parameter settings.

The MKII can be recognized externally by the slightly wider spaced winding plates for operating longer tapes and, above all, by the small plastic bars mounted on the right and left between the large and small deflection pulleys. The belt guide of the STUDER B67 is exemplary: Two large deflection pulleys on the right and left and one small swiveling deflection pulley each for regulating the belt tension. The large deflection roller on the right - fitted with a rubber ring in the belt guide - is used to control the digital counter, which, however, does not yet automatically adjust to the respective belt speed (9.5 - 19 - 38 cm/sec), as is the case with later STUDER belt machines. The speed selection buttons on the STUDER B67 are located directly to the right of the counter. The most important buttons for operating the drive are located in the center: Fast Rewind, Fast Forward, Play, Stop and Record. In the left part of the keypad are the buttons for controlling special functions.

- Helpful when cutting was the MOT.OFF button, which fed the tape out of the headstock area as desired without being rewound by the right winding motor. Another button, the repeat button - right next to the power switch on the far left - has two functions in one: When pressed, it interrupts the recording or playback function with simultaneous fast rewind; when released, the unit automatically switches to playback. Another important button is the AUTO button. Depending on the programming of the B67, two automatic functions are possible. The first is to automatically rewind at the end of the tape and then switch to stop, the second is to fast rewind after reaching the end of the tape and then play again. In this operating mode, the STUDER B67 can thus perform its duties without interruption.

- All important drive buttons of the STUDER B67 are illuminated when the function is switched on. On this VU-Meter B67, the controls for the recording and playback signals are arranged to the right and left of the large, clearly arranged VU-Meter. In the "Uncal" position - this is controlled by the small round button below the knobs - the knobs influence the strength of the respective signal, in the "Cal" position - Cal stands for "calibrated" - a fixed studio level is preset. Which signal is displayed by the level controls is determined in the bar above the knobs. The buttons are called Inp(ut), Reprod(uction) and on some machines also Sync(hronisation). The SAFE button - on the left - protects against unintentional recording and erasure of recorded tapes.

The headstock of the STUDER B67 MK II VU is equipped with butterfly heads - separating track 0.75 millimetres. For stereo operation, Schmetterling tape heads offer the optimum compromise between the best utilisation of the tape width and the risk of cross-talk between the tracks.